FRP/PVC-C, FRP/PVC-U Fiberglass Reinforced Plastic Coated Flange

FRP/PVC-C, FRP/PVC-U Fiberglass Reinforced Plastic Coated Flange

| App Temperature Bound List |

| Material | Medium temperature℃ | Material | Medium temperature℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||

| PVC-C | -20℃~+95℃ | PVC-U | -5℃~+45℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||

| FRPP | -20℃~+120℃ | PPH | -20℃~+110℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||

| PVDF | 40℃~+150℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Structural Features |

1. Lightweight and High-Strength

The relative density is between 1.5 and 2.0, only 1/4 to 1/5 that of carbon steel, yet its tensile strength approaches or even exceeds that of carbon steel, and its specific strength is comparable to that of high-grade alloy steel.

2. Excellent Corrosion Resistance

FRP is an excellent corrosion-resistant material, offering excellent resistance to air, water, moderate concentrations of acids, alkalis, salts, and various oils and solvents.

3. Excellent Electrical Properties

FRP is an excellent insulating material used in insulators. It maintains good dielectric properties even at high frequencies and has excellent microwave transmittance.

4. Excellent Thermal Properties

FRP has low thermal conductivity and is The thermal conductivity is 1.25-1.67 kJ/s, only 1/100-1/1000 of that of metal, making it an excellent thermal insulation material.

5. Excellent Designability

Flexible design of various structural products to meet specific application requirements, ensuring excellent product integrity and enabling the selection of materials to meet product performance requirements.

6. Excellent Manufacturability

Flexible molding technology can be selected based on product shape, technical requirements, application, and quantity. The process is simple, allows for one-step molding, and offers excellent economic benefits. This is particularly advantageous for complex, challenging, and low-volume products, highlighting its superior processability.

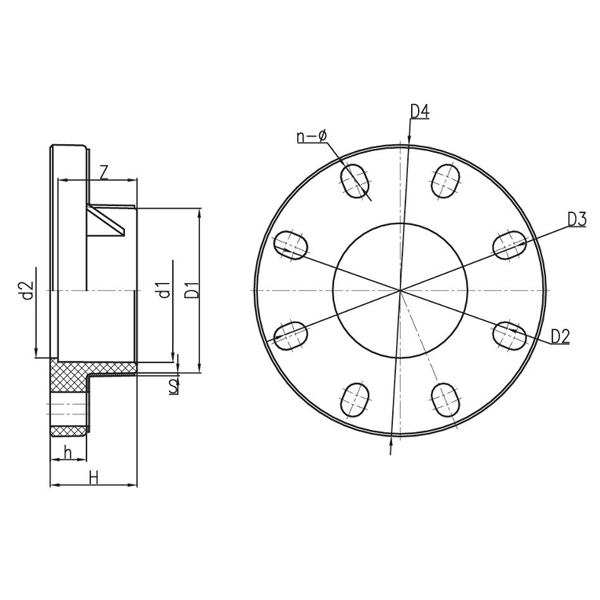

| Composite Flange |

| DN | D1 | D2 | D3 | D4 | d1 | d2 | H | h | Z | S | n-Φ | ||||||||||||||||||||||||||||||||||||||||||||

| 0.6MPa | 1.0MPa | 1.6MPa | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 30 | 65 | 70 | 95 | 20 | 17 | 20 | 14 | 16 | 12 | 14 | 16 | 4-Φ15X20 | ||||||||||||||||||||||||||||||||||||||||||

| 20 | 36 | 70 | 75 | 105 | 25 | 22 | 23 | 16 | 19 | 12 | 14 | 16 | 4-Φ15X18 | ||||||||||||||||||||||||||||||||||||||||||

| 25 | 46 | 79 | 90 | 120 | 32 | 28 | 27 | 16 | 22 | 12 | 14 | 18 | 4-Φ16X22 | ||||||||||||||||||||||||||||||||||||||||||

| 32 | 53 | 89 | 100 | 140 | 40 | 36 | 31 | 17 | 26 | 12 | 16 | 18 | 4-Φ18X24 | ||||||||||||||||||||||||||||||||||||||||||

| 40 | 64 | 98 | 110 | 150 | 50 | 45 | 36 | 19 | 31 | 12 | 18 | 20 | 4-Φ18X25 | ||||||||||||||||||||||||||||||||||||||||||

| 50 | 77 | 120 | 125 | 165 | 63 | 58 | 43 | 21 | 38 | 15 | 18 | 20 | 4-Φ18X21 | ||||||||||||||||||||||||||||||||||||||||||

| 65 | 92 | 140 | 145 | 185 | 75 | 69 | 50 | 22 | 44 | 18 | 20 | 25 | 4-Φ18X21 | ||||||||||||||||||||||||||||||||||||||||||

| 80 | 108 | 150 | 160 | 200 | 90 | 84 | 57 | 25 | 51 | 18 | 20 | 25 | 8-Φ18X24 | ||||||||||||||||||||||||||||||||||||||||||

| 100 | 131 | 175 | 190.5 | 225 | 110 | 104 | 67 | 28 | 61 | 18 | 20 | 25 | 8-Φ18X26 | ||||||||||||||||||||||||||||||||||||||||||

| 125 | 160 | 210 | 216 | 250 | 140 | 134 | 82 | 30 | 76 | 18 | 25 | 30 | 8-Φ20X22 | ||||||||||||||||||||||||||||||||||||||||||

| 150 | 180 | 240 | 242 | 280 | 160 | 154 | 92 | 30 | 86 | 18 | 25 | 30 | 8-Φ23X24 | ||||||||||||||||||||||||||||||||||||||||||

| 200(PN10) | 253 | 290 | 295 | 338 | 225 | 219 | 125 | 35 | 119 | 20 | 30 | 35 | 8-Φ23X27 | ||||||||||||||||||||||||||||||||||||||||||

| 200(PN16) | 249 | — | 295 | 340 | 225 | 219 | 125 | 28 | 119 | 20 | 30 | 35 | 12-Φ23 | ||||||||||||||||||||||||||||||||||||||||||

| 250 | 310 | 350 | 362 | 406 | 280 | 254 | 153 | 30 | 146 | 25 | 35 | 40 | 12-Φ25X31 | ||||||||||||||||||||||||||||||||||||||||||

| 300 | 348 | 400 | 432 | 483 | 315 | 300 | 174 | 30 | 164 | 25 | 35 | 45 | 12-Φ25X41 | ||||||||||||||||||||||||||||||||||||||||||

| 350 | 393 | 460 | 470 | 520 | 355 | 348 | 197 | 35 | 184 | 30 | 40 | 50 | 16-Φ22X27 | ||||||||||||||||||||||||||||||||||||||||||

| 400 | 440 | 515 | 525 | 580 | 400 | 390 | 218 | 35 | 206 | 30 | 40 | 60 | 16-Φ26X31 | ||||||||||||||||||||||||||||||||||||||||||

| 450 | 494 | 561 | 589 | 640 | 450 | 430 | 243 | 40 | 231 | 35 | 45 | 65 | 20-Φ26X36 | ||||||||||||||||||||||||||||||||||||||||||

| 500 | 548 | 620 | 650 | 715 | 500 | 480 | 271 | 40 | 256 | 35 | 50 | 70 | 20-Φ26X41 | ||||||||||||||||||||||||||||||||||||||||||

| 600 | 692 | 725 | 780 | 840 | 630 | 571 | 506 | 42 | 321 | 40 | 55 | 75 | 20-Φ30X58 | ||||||||||||||||||||||||||||||||||||||||||

1. Proper Surface Preparation of Pipes and Fittings Proper surface preparation is essential for ensuring a secure, leak-free joint between PPH pipe fittings and...

READ MOREThe smoothness of the internal surfaces is one of the most crucial design features of PPH Plastic Pipe Valve that helps prevent clogging and build-up, particula...

READ MORETemperature ResistancePVDF (Polyvinylidene Fluoride) plastic is known for its relatively high temperature resistance compared to many other plastics, with the a...

READ MOREPrecision-Molded Valve Body and Internal ComponentsPPH Plastic Pipe Valves are manufactured from high-quality polypropylene homopolymer (PPH), a material know...

READ MORE