| App Temperature Bound List |

| Material | Medium temperature℃ | Material | Medium temperature℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||

| PVC-C | -20℃~+95℃ | PVC-U | -5℃~+45℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||

| FRPP | -20℃~+120℃ | PPH | -20℃~+110℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||

| PVDF | 40℃~+150℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Structural Features |

1. Lightweight: PVC-U is only 1/10 the weight of cast iron, making it easy to transport and install, reducing costs.

2. Superior Chemical Resistance: PVC-U has excellent resistance to acids and alkalis, with the exception of strong acids and alkalis near their saturation point.

3. Durable: PVC-U offers excellent weather resistance and is resistant to corrosion by bacteria and fungi.

4. Non-conductive: PVC-U is non-conductive and is not susceptible to corrosion by electrolysis or electric current, eliminating the need for secondary processing. It is non-flammable and does not support combustion, eliminating fire safety concerns.

5. Low resistance and high flow rate: The smooth inner wall minimizes fluid flow loss, and dirt is less likely to adhere to the smooth pipe surface, making maintenance simple and cost-effective.

6. Easy Installation and Low Cost: Cutting and joining are simple. PVC glue has proven to be safe, reliable, easy to use, and cost-effective.

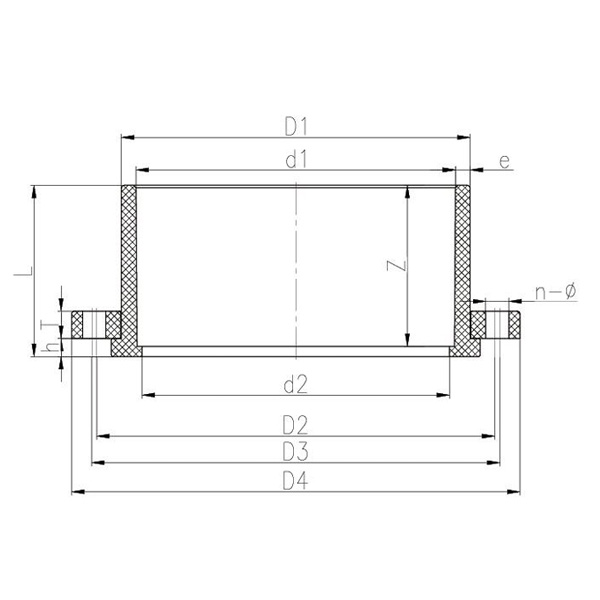

| PVC-U Vanstone Flange |

| DN | D1 | D2 | D3 | D4 | d1 | d2 | L | T | h | Z | n-Φ | |||||||||||||||||||||

| 15 | 27 | 59 | 70 | 95 | 20 | 18 | 22 | 16 | 1.5 | 16 | 4-Φ15X20.5 | |||||||||||||||||||||

| 20 | 32 | 70 | 75 | 105 | 25 | 23 | 25 | 18 | 1.5 | 19 | 4-15X17.5 | |||||||||||||||||||||

| 25 | 40 | 79 | 90 | 125 | 32 | 29 | 28 | 18 | 1.5 | 22 | 4-Φ15X20.5 | |||||||||||||||||||||

| 32 | 50 | 89 | 100 | 140 | 40 | 36 | 31.5 | 20 | 1.5 | 26 | 4-Φ18X24.5 | |||||||||||||||||||||

| 4 | 61 | 98 | 110 | 150 | 50 | 4 | 37 | 20 | 2 | 31 | 4-Φ18X24 | |||||||||||||||||||||

| 50 | 75 | 120 | 125 | 165 | 63 | 58 | 44 | 25 | 2 | 38 | 4-Φ18X20.5 | |||||||||||||||||||||

| 65 | 88 | 140 | 145 | 185 | 75 | 69 | 50 | 25 | 2 | 44 | 4-Φ18X20.5 | |||||||||||||||||||||

| 80 | 105 | 150 | 160 | 200 | 90 | 84 | 57 | 26 | 2.5 | 51 | 8-Φ18X23 | |||||||||||||||||||||

| 100 | 127 | 175 | 190.5 | 229 | 110 | 105 | 67 | 26 | 2.5 | 61 | 8-Φ18X26 | |||||||||||||||||||||

| 125 | 161 | 210 | 250 | 140 | 130 | 84 | 28 | 12.5 | 77 | 8-Φ19 | ||||||||||||||||||||||

| 150 | 182 | 240 | 285 | 160 | 150 | 93 | 31 | 12.5 | 85 | 8-Φ23 | ||||||||||||||||||||||

| 200 | 249 | 295 | 339 | 225 | 215 | 127 | 36 | 16 | 119 | 8-Φ23X25 | ||||||||||||||||||||||

| 200 | 254 | 295.8 | 341 | 225 | 215 | 127 | 33.1 | 16 | 119 | 12-Φ22 | ||||||||||||||||||||||

| 250 | 308 | 350 | 395 | 280 | 267 | 154 | 40.5 | 16.5 | 144 | 12-Φ23 | ||||||||||||||||||||||

| 300 | 346 | 400 | 445 | 315 | 305 | 170 | 43 | 18 | 160 | 12-Φ23 | ||||||||||||||||||||||

| 350 | 395 | 460 | 505 | 355 | 340 | 176 | 43 | 16 | 164.5 | 16-Φ23 | ||||||||||||||||||||||

| 400 | 442 | 515 | 570 | 400 | 382 | 219 | 43 | 22 | 200 | 16-Φ27 | ||||||||||||||||||||||

| 450 | 494 | 565 | 625 | 450 | 430 | 220 | 40 | 27 | 210 | 20-Φ26 | ||||||||||||||||||||||

| 500 | 548 | 620 | 670 | 500 | 475 | 210 | 43 | 25 | 185 | 20-Φ27 | ||||||||||||||||||||||

Streamlined Flow Path and Valve Geometry: The internal geometry of a CPVC check valve is critical in minimizing pressure drop while allowing smooth fluid flow...

READ MOREMaterial Selection and Seal Integrity: The material composition of internal seals or discs in a CPVC check valve is crucial to both leakage prevention and lon...

READ MOREFlow Requirements (Pipe Diameter)The diameter of a plastic pipe directly impacts its flow capacity, as larger pipes allow for a higher volume of fluid to pass...

READ MORE1. Proper Surface Preparation of Pipes and Fittings Proper surface preparation is essential for ensuring a secure, leak-free joint between PPH pipe fittings and...

READ MORE