| App Temperature Bound List |

| Material | Medium temperature℃ | Material | Medium temperature℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||

| PVC-C | -20℃~+95℃ | PVC-U | -5℃~+45℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||

| FRPP | -20℃~+120℃ | PPH | -20℃~+110℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||

| PVDF | 40℃~+150℃ | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Structural Features |

1. Excellent Heat Resistance

Reinforced polypropylene is a material made by adding glass fiber to pure PP, expanding its application range. Its enhanced heat resistance overcomes the inherent mechanical strength disadvantage of PP, while maintaining its excellent corrosion resistance and increasing its operating temperature.

2. High Mechanical Strength and Excellent Wear Resistance

Its strength, stiffness, hardness, and heat resistance surpass those of low-pressure polyethylene.

Its low linear expansion coefficient provides excellent acid, alkali, and heat resistance.

3. Excellent Impact Toughness

Molding Shrinkage: 1.0-2.5%, significantly reducing shrinkage and significantly improving stiffness. It offers excellent electrical properties and high-frequency insulation, unaffected by humidity.

4. Wide Range of Applications

FRPP, due to its low material cost, long service life, and easy installation, is widely used in piping systems for the chemical, chemical fiber, chlorine-alkali, dye, water supply and drainage, food, pharmaceutical, sewage treatment, and electrolysis industries.

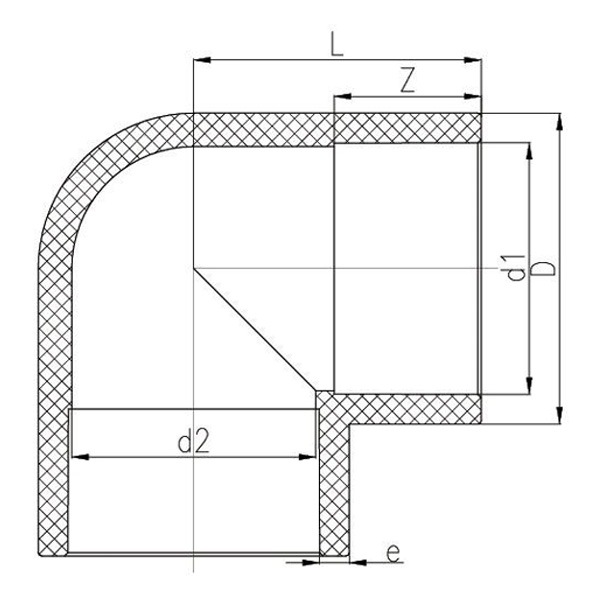

| FRPP 90°elbow |

| DN | D | d1 | d2 | L | Z | e | |||||||||||||||||||||

| 15 | 25.5 | 20 | 16 | 28.75 | 16 | 2.75 | |||||||||||||||||||||

| 20 | 31 | 25 | 20 | 35.5 | 19.5 | 3 | |||||||||||||||||||||

| 25 | 40 | 32 | 27 | 43.5 | 22.5 | 4 | |||||||||||||||||||||

| 32 | 49 | 40 | 34 | 45.5 | 21 | 4.5 | |||||||||||||||||||||

| 40 | 60 | 50 | 44 | 58.5 | 26 | 5 | |||||||||||||||||||||

| 50 | 74.5 | 63 | 57 | 76.75 | 40.5 | 5.75 | |||||||||||||||||||||

| 65 | 85 | 75 | 73 | 82.5 | 40 | 5 | |||||||||||||||||||||

| 80 | 102 | 90 | 87 | 99 | 42 | 6 | |||||||||||||||||||||

| 100 | 124 | 110 | 106 | 123 | 55 | 7 | |||||||||||||||||||||

| 125 | 158 | 140 | 135 | 144 | 63.5 | 9 | |||||||||||||||||||||

| 150 | 178 | 160 | 156 | 170 | 83 | 9 | |||||||||||||||||||||

| 200 | 251 | 225 | 216 | 243.5 | 109.5 | 13 | |||||||||||||||||||||

1. Proper Surface Preparation of Pipes and Fittings Proper surface preparation is essential for ensuring a secure, leak-free joint between PPH pipe fittings and...

READ MOREThe smoothness of the internal surfaces is one of the most crucial design features of PPH Plastic Pipe Valve that helps prevent clogging and build-up, particula...

READ MORETemperature ResistancePVDF (Polyvinylidene Fluoride) plastic is known for its relatively high temperature resistance compared to many other plastics, with the a...

READ MOREPrecision-Molded Valve Body and Internal ComponentsPPH Plastic Pipe Valves are manufactured from high-quality polypropylene homopolymer (PPH), a material know...

READ MORE