Kaixin Pipeline Technologies Co., Ltd.

Founded in 1999, Kaixin Pipeline Technologies Co., Ltd. is a high-tech enterprise integrating R&D, manufacturing, sales, and service. As a famous

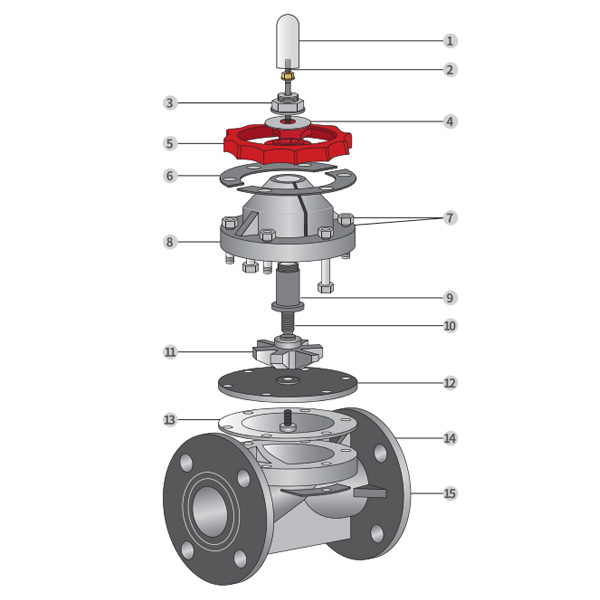

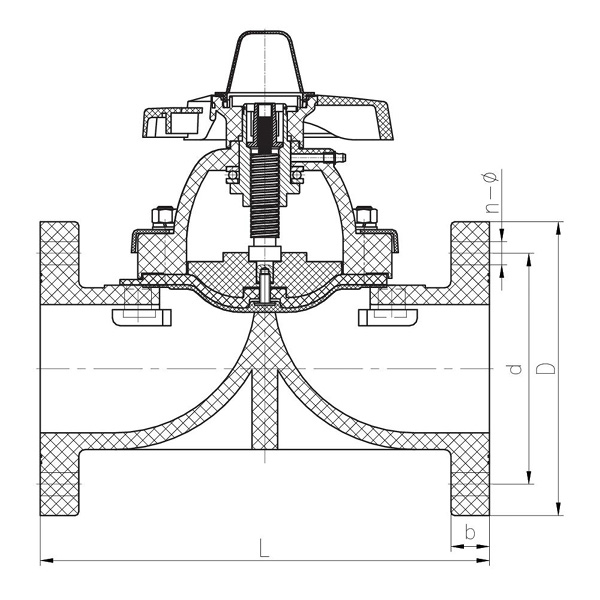

China PPH G41F-10S Flange Type Diaphragm Valve DN15-300 GB Standard Suppliers and

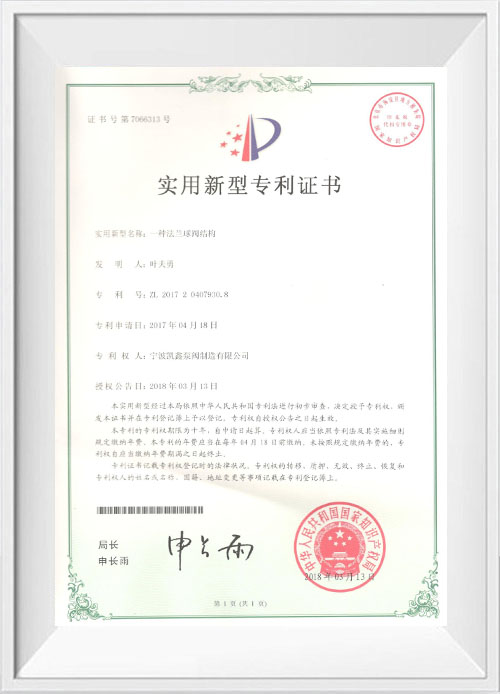

PPH G41F-10S Flange Type Diaphragm Valve DN15-300 GB Standard Factory, the company holds multiple prestigious certifications, including National High-Tech Enterprise, “Little Giant” Specialized and Sophisticated SME, National Single Product Champion (Cultivation), Provincial Technology-based SME, Ningbo Specialized and Sophisticated SME, Ningbo Single Product Champion (Cultivation), Ningbo Polymer Pipe & Valve Technology R&D Center, District-Level Green Factory, Ningbo Four-Star Management Innovation Enterprise, and Enterprise Data Management Capability Maturity Level 2.

We specialize in developing, producing, and supplying non-metallic corrosion-resistant products for chemical applications, including plastic valves, pipes, pipe fittings, and corrosion-resistant pumps. Our product portfolio spans materials such as PVC-C, PVC-U, PVDF, PPH, and FRPP, with a comprehensive range of types and specifications. Notably, our butterfly valves can reach DN1000 in diameter, while pipes and fittings extend up to DN800, addressing market gaps and maintaining our competitive edge in the industry.

Guided by the principle of “Technology-Driven, Keeping Pace with the Times,” Kaixin allocates nearly RMB 10 million annually to R&D. We ensure superior product quality through standardized automated manufacturing and strict sourcing of imported raw materials. Aligned with our international development strategy, we continuously monitor global market trends and leverage digital channels to bring high-quality “Made in China” products to customers worldwide.

Ningbo • Fenghua R&D & Production Base

With a total investment of RMB 200 million, Kaixin Ultra-Pure Pipe Technology (Ningbo) Co., Ltd. has established a new materials laboratory in collaboration with universities and research institutes, built a modern manufacturing base, and installed 8 fully automated production lines for modified plastics and 8 for polymer materials. The facility is dedicated to the R&D, production, and application of new modified plastics and polymer materials. Kaixin is also committed to attracting top talent across disciplines, continuously driving product innovation and brand development, with the goal of becoming a globally recognized leader in the R&D and manufacture of polymer valves, pipes, and fittings.

EN

EN English

English 中文简体

中文简体

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

+86-18067123177

+86-18067123177