What are the working principles and design features of a Sight Glass?

A Sight Glass is a transparent window installed on pipes, tanks, or other enclosed containers, allowing operators to observe the state of the liquid, such as liquid level, flow rate, color, and clarity. Its working principles and design features are crucial in industrial environments, ensuring that operators can clearly understand changes and flow of the liquid without interfering with the internal conditions of the container or pipe.

Working Principles

The working principle of a Sight Glass is very simple, yet its function is powerful. Through the transparent window, operators can directly see the state of the liquid inside the container. When the liquid passes through the Sight Glass, the transparent section provides clear visual feedback to the operator. Its working method mainly includes the following aspects:

- Liquid Level Observation: One of the most common applications of a Sight Glass is monitoring liquid levels. As the liquid passes through the Sight Glass, operators can visually see the position of the liquid surface to confirm the liquid level in the container, preventing overflow or drying out. Accurate liquid level control is especially crucial in tanks, boilers, chemical reaction vessels, and other applications.

- Flow Monitoring: In fluid pipelines, Sight Glasses are also used to observe the flow state of the fluid. Operators can determine the flow rate and flow pattern through the transparent window, understanding whether the pipeline is blocked or experiencing abnormal flow.

- Reaction Monitoring: In chemical reaction processes, the Sight Glass provides a visual monitoring method, helping operators observe color changes, foam formation, etc., in the reaction liquid, allowing for timely adjustment of reaction conditions.

- Safety Monitoring: In many industrial processes, the design of the Sight Glass considers the visibility of the process liquid, allowing operators to determine if there are dangerous liquid leaks, corrosion, or contamination. Through it, operators can avoid dangers caused by system failures or improper operation.

Design Features

The design of a Sight Glass includes several aspects to ensure stable performance in different applications:

- Transparency: The transparent window is the core feature of a Sight Glass, usually made of materials such as tempered glass, polycarbonate (PC), or acrylic (PMMA). These materials have good optical transparency, allowing operators to clearly observe the internal liquid.

- Pressure and Temperature Resistance: To withstand the high pressure and high temperature conditions in industrial environments, Sight Glasses are typically designed with enhanced pressure and temperature resistance. They must be able to withstand prolonged operating pressure in high-pressure fluid or steam systems without cracking or leaking.

- Corrosion Resistance: Because many industrial environments involve corrosive liquids (such as acids, alkalis, or salt solutions), the materials used for Sight Glasses need to have strong corrosion resistance. Common materials include PVC, PVDF, and FRPP, which effectively prevent corrosion and damage during chemical processing.

- Sealing Performance: The interface between the Sight Glass and the container or pipe requires an effective sealing system to prevent leaks. Common sealing materials include rubber gaskets and PTFE. Good sealing ensures that even under high pressure or high temperature conditions, liquid will not leak from the joints, preventing safety hazards.

- Structural Durability: The structure of the Sight Glass needs to be robust enough to withstand external impacts and vibrations, especially in industrial production lines. Reinforced materials and support structure designs extend their service life and reduce the risk of equipment failure.

- Protective Functions: In some harsh environments, Sight Glasses may also be designed to be explosion-proof or UV-resistant to meet extreme conditions or special application requirements.

Which specific industrial applications are suitable for Sight Glasses made of different materials?

Different materials possess different physical and chemical properties, which determine the environments in which they are suitable for use. For Sight Glasses, depending on the material used, they are suitable for different industries and application scenarios.

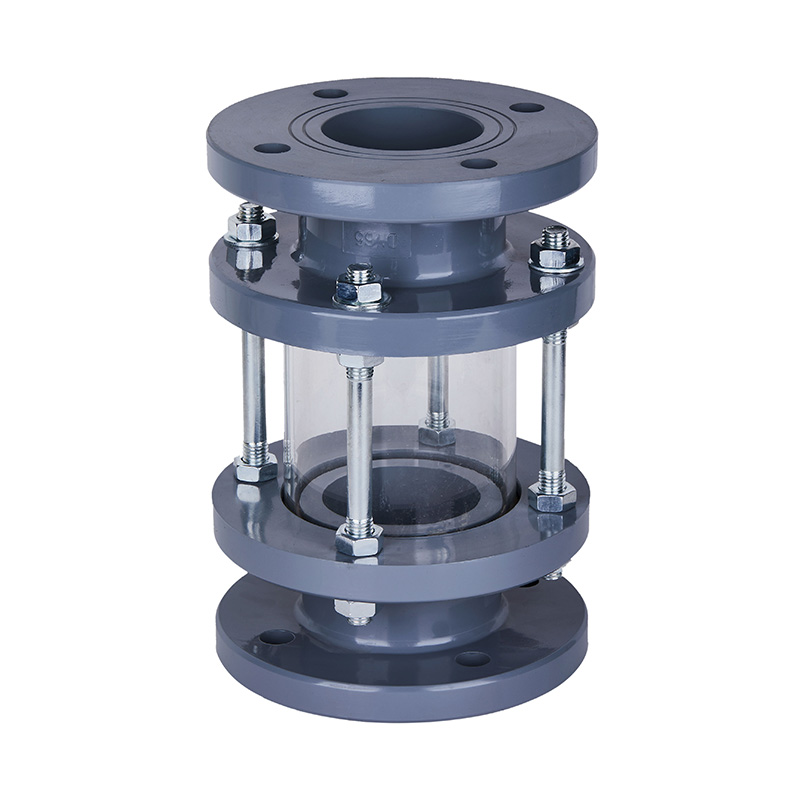

PVC-C (Chlorinated Polyvinyl Chloride)

- Features: PVC-C has stronger high-temperature resistance and chemical corrosion resistance than ordinary PVC, allowing it to operate at higher temperatures while maintaining good corrosion resistance. It is cost-effective and suitable for environments with temperatures not exceeding 90°C.

- Applications: PVC-C Sight Glasses are suitable for water treatment, wastewater treatment, and certain chemical plants, especially when handling acid, alkaline, or saline solutions in low to medium temperature environments. Due to its excellent chemical resistance, it is often used for monitoring the flow of common chemical liquids.

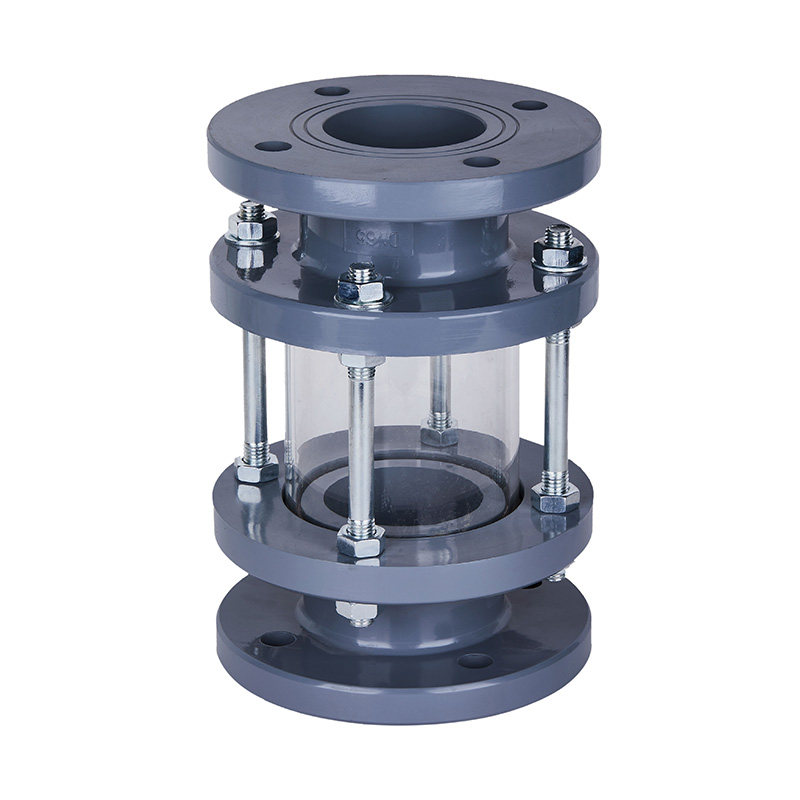

PVC-U (Unplasticized Polyvinyl Chloride)

- Features: PVC-U is a rigid plastic with excellent corrosion resistance. It is suitable for common chemical media, has high strength, but its high-temperature resistance is relatively poor (approximately 60-70°C).

- Applications: PVC-U Sight Glasses are commonly used in water treatment plants, food processing plants, and other fields where there are no strong requirements for the liquid medium. It is particularly suitable for water and wastewater treatment and monitoring of low-corrosive chemicals.

PVDF (Polyvinylidene Fluoride)

- Features: PVDF is a material with high strength, high-temperature resistance, and excellent chemical resistance, capable of withstanding extreme chemical media such as strong acids and bases. PVDF has strong weather resistance and mechanical properties, making it suitable for high-temperature (up to 150°C) and highly corrosive environments.

- Applications: PVDF Sight Glasses are commonly used in the pharmaceutical industry, chemical processing, electronics manufacturing, and other industries, especially in applications requiring strict chemical stability and freedom from contamination. It effectively resists corrosion and is suitable for monitoring highly corrosive liquids, such as acidic or alkaline solutions.

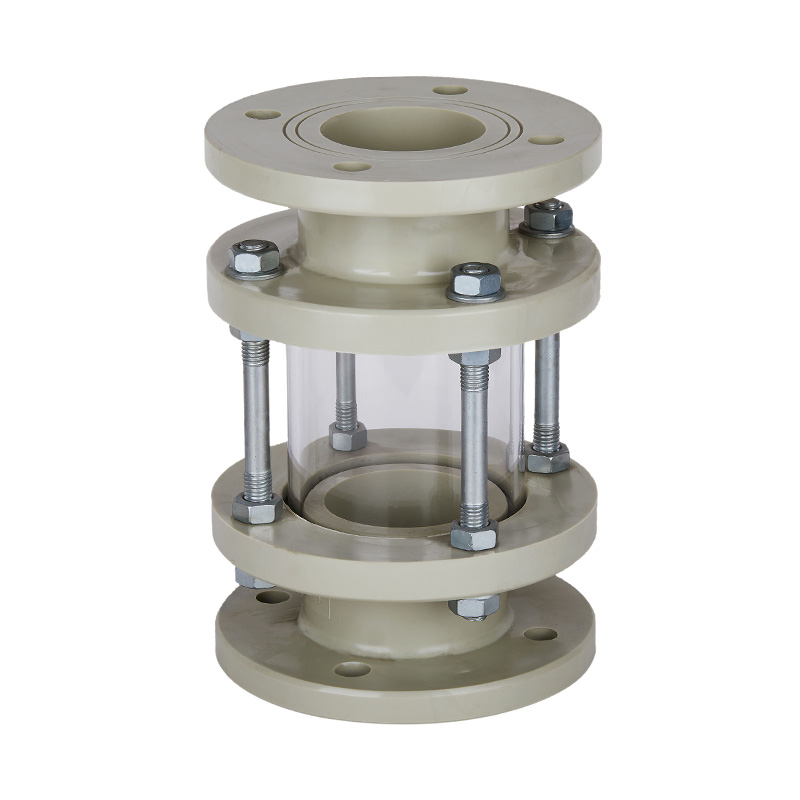

PPH (Polyphenylene Ether)

- Features: PPH is a high-strength, heat-resistant material with excellent chemical resistance, suitable for high-temperature and high-pressure environments. PPH has strong oxidation resistance and corrosion resistance, and can withstand temperatures up to 160°C.

- Applications: PPH Sight Glasses are commonly used in high-temperature and high-pressure environments such as petrochemicals, fertilizer production, and water treatment facilities, providing strong durability, especially when handling complex chemical solutions in these environments.

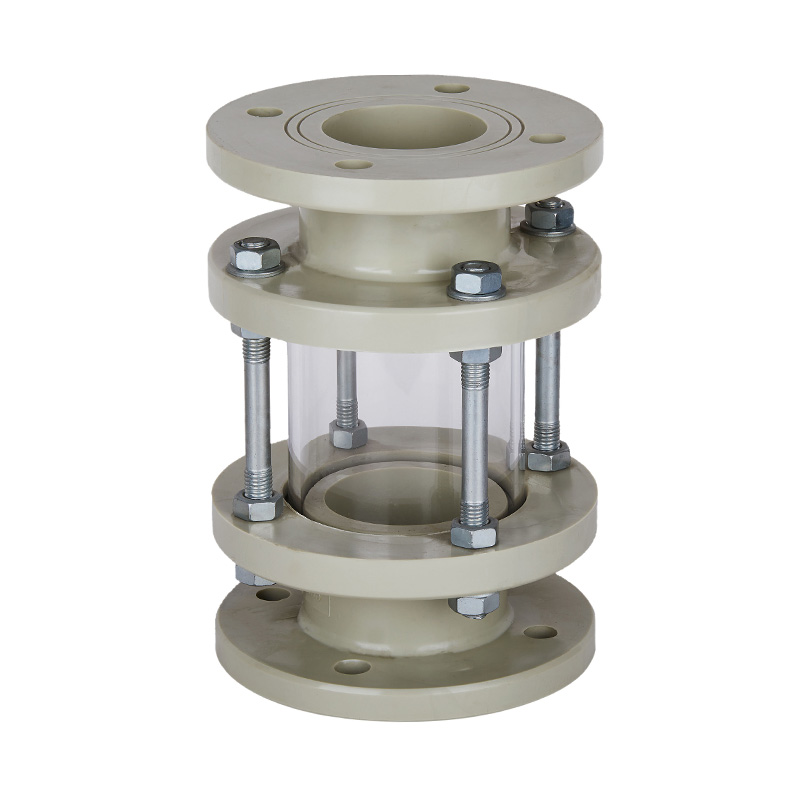

FRPP (Fiber Reinforced Polypropylene)

- Features: FRPP is a composite material reinforced with glass fibers, possessing higher strength and corrosion resistance. It has excellent high-temperature resistance, suitable for use in complex chemical environments. FRPP has higher temperature resistance than ordinary polypropylene and possesses strong mechanical strength and wear resistance.

- Applications: FRPP Sight Glasses are widely used in petrochemicals, chemical industry, and water treatment, especially suitable for handling highly acidic and corrosive fluids. Its high-temperature resistance makes it suitable for long-term use in industrial equipment.

What are the maintenance and cleaning requirements for Sight Glasses?

Sight glasses play a crucial role in industrial applications, and their maintenance and cleaning requirements are key factors in ensuring their long-term reliable operation. Over time, sight glasses may experience reduced transparency or damage due to fluid contamination, sediment accumulation, or corrosion. Therefore, regular inspection, cleaning, and maintenance are essential.

Regular Inspection

Regular inspection is the first step in ensuring the proper functioning of the sight glass and preventing potential problems. In industries such as chemical, petroleum, and water treatment, the liquid components are often complex, and the chemical properties of the fluid can lead to aging, corrosion, or wear of the sight glass material.

- Transparency Check: Over time, the transparent part of the sight glass may become cloudy or hazy due to fluid deposits, corrosive substances, or chemical reactions. Operators should regularly check the transparency of the viewing surface; if transparency decreases, cleaning or replacement is necessary.

- Seal Integrity Check: The sealing parts of the sight glass must be leak-proof. Regularly inspect the seals, joints, and connections to ensure there is no damage due to chemical corrosion or high temperature and pressure. If the sealing material is found to be aged or damaged, it should be replaced promptly.

- Mechanical Damage Check: Long-term use may cause cracks or scratches in the sight glass, especially in high-pressure or high-temperature environments. The sight glass should be regularly inspected for such damage; if damage is found, it needs to be replaced or repaired promptly.

Cleaning Requirements

To ensure the effectiveness of the sight glass during long-term use, cleaning is another important maintenance aspect. The fluid may contain particulate matter, grease, and sediment, which can affect the transparency of the viewing window, thus affecting the operator's monitoring of the liquid level or flow state.

- Cleaning Frequency: The frequency of cleaning depends on the characteristics of the fluid being processed. If the fluid is highly viscous or contains many particles, the sight glass needs to be cleaned more frequently. For high-temperature or highly corrosive fluids, frequent inspection should also be considered to prevent the accumulation of chemical residues from damaging the viewing window.

- Cleaning Method: Use a mild cleaning agent and a soft cloth for cleaning. Avoid using strong acid or alkaline cleaning agents, as these may damage the surface material of the Sight Glass. For stubborn stains or deposits, a soft-bristled brush can be used for mechanical cleaning, but avoid using metal brushes to prevent scratching the transparent surface.

- Self-cleaning design: In some industrial applications, Kaixin Pipeline Technologies Co., Ltd. may provide Sight Glass solutions with self-cleaning capabilities based on customer needs. For example, adding special coatings or designing equipment with cleaning functions can help reduce daily maintenance requirements.

Corrosion Prevention and Maintenance

Since Sight Glasses are often used for monitoring chemical or corrosive liquids, corrosion prevention measures are crucial. Regularly checking for corrosion and taking steps to prevent direct contact with corrosive fluids is key to extending their service life.

- Selection of corrosion-resistant materials: Choosing materials with high corrosion resistance is essential depending on the application environment. For example, using chemically resistant materials such as PVDF, FRPP, or PPH can effectively prevent corrosive liquids from damaging the Sight Glass. Kaixin Pipeline Technologies Co., Ltd. offers a variety of Sight Glass materials suitable for different corrosive fluids, allowing customers to choose the most appropriate material based on their actual application needs.

- Corrosion inspection: Sight Glasses used in chemical, petroleum, or other corrosive environments require regular inspection for signs of corrosion, especially when exposed to strong acids, bases, or salt solutions. Operators should regularly inspect the sealing joints, transparent surface, and support structure to ensure there are no leaks or damage due to corrosion.

Seal Maintenance and Replacement

Maintaining the sealing parts is crucial for ensuring the proper functioning of the Sight Glass, especially in high-pressure or high-temperature environments. Since sealing materials are prone to aging or wear, regular inspection and replacement are necessary.

- Seal inspection: The sealing parts of the Sight Glass typically use materials such as rubber gaskets and PTFE (polytetrafluoroethylene) seals, which must have good chemical and temperature resistance. Regularly check the seals for cracks, aging, or hardening. If these problems are found, they should be replaced promptly.

- Replace Damaged Parts Promptly: If leakage of liquid or gas is detected in the sealing part of the Sight Glass, or if there are irreparable cracks on the transparent surface, stop using it immediately and replace it. Especially in applications involving hazardous chemicals, damage to the seal can lead to serious safety accidents.

Kaixin Pipeline Technologies Co., Ltd.'s Customized Services and Maintenance Support

Kaixin Pipeline Technologies Co., Ltd. provides one-stop procurement services, ensuring that customers can find solutions that meet their needs in products such as pipes, valves, pumps, and Sight Glasses. The company not only provides standard products but also offers customized services to help customers select the most suitable materials and designs based on their specific requirements.

- Customized Design: Kaixin Pipeline Technologies Co., Ltd.'s professional team can provide OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services based on samples or drawings provided by customers, ensuring that the products meet the functional requirements of customers in specific applications. Especially in special environments requiring corrosion resistance, high temperature resistance, and high pressure resistance, customers can customize suitable Sight Glass solutions according to their actual needs.

- Technical Support and Service: The company not only provides products but also has a professional sales and service team to provide comprehensive services from initial selection to after-sales maintenance. During the use of the Sight Glass, customers can receive one-on-one technical support to ensure that their maintenance and cleaning work is professionally guided.

- Quality Assurance: Every batch of products from Kaixin Pipeline Technologies Co., Ltd. undergoes rigorous internal testing to ensure that its quality meets international standards. The company also provides customers with detailed test reports and inspection reports, ensuring the long-term stable operation of the Sight Glass in applications.

Through these services, Kaixin Pipeline Technologies Co., Ltd. not only helps customers choose the right materials and designs but also provides them with best practices for maintenance and cleaning, ensuring the long-term stability and operational efficiency of the equipment.

EN

EN English

English

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

+86-18067123177

+86-18067123177