Design Innovations Enhancing CPVC Plastic Valve Functionality

CPVC Plastic Valves must resist mechanical stress, high pressures, and thermal variations without deformation or failure. Kaixin Pipeline Technologies Co., Ltd. enhances structural reinforcement by integrating thicker wall sections, internal ribs, and high-performance CPVC resin blends that maintain dimensional stability under industrial conditions. Reinforcement ensures large-diameter valves, including butterfly valves up to DN1000, can handle torsional forces during operation and maintain proper alignment with connecting pipes. Even in high-pressure chemical transport, reinforced valve bodies distribute mechanical load evenly, preventing localized stress concentrations and minimizing the risk of cracks or leaks. Reinforced structures provide resistance to thermal expansion, pressure cycling, and long-term fatigue, increasing operational reliability. Kaixin also optimizes reinforcement design to avoid excessive weight, enabling easier installation and support in piping networks. By combining engineering analysis with premium CPVC materials, our valves maintain mechanical integrity and consistent performance across industrial applications, including chemical processing, water treatment, and pharmaceutical systems. Reinforced bodies reduce maintenance frequency, extending service life and ensuring system stability over extended operation.

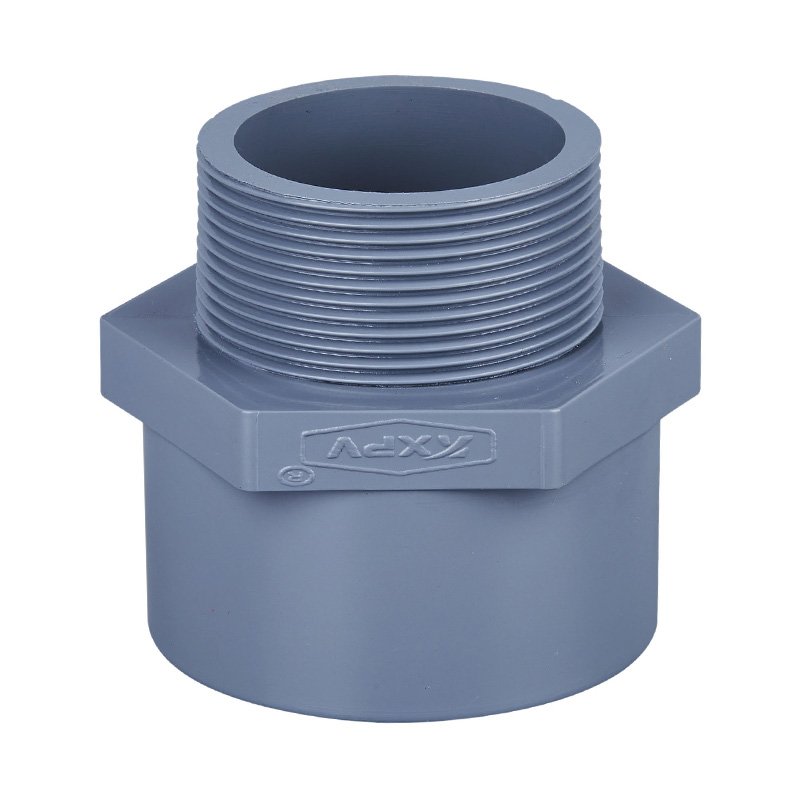

Sealing efficiency is critical for CPVC Plastic Valves to maintain leak-free operation under various pressures, temperatures, and chemical exposures. Kaixin Pipeline Technologies Co., Ltd. achieves sealing optimization through precision-engineered valve seats, gaskets, and O-rings constructed from chemically compatible polymers. The contact interface between the valve disc and seat is carefully designed to ensure uniform compression and minimal operational torque, allowing smooth valve actuation while preventing leaks. For systems handling hot or corrosive chemicals, thermally stable and chemically resistant sealing components maintain their shape and performance over prolonged cycles. Modular seat designs allow inspection, replacement, or adjustment without disassembling the entire valve or piping system, reducing downtime and maintenance effort. Improved sealing efficiency also supports energy savings by minimizing pressure losses and ensures precise flow control in automated industrial processes. Kaixin’s design innovations provide reliable sealing even in aggressive industrial environments, ensuring consistent performance, safety, and operational efficiency.

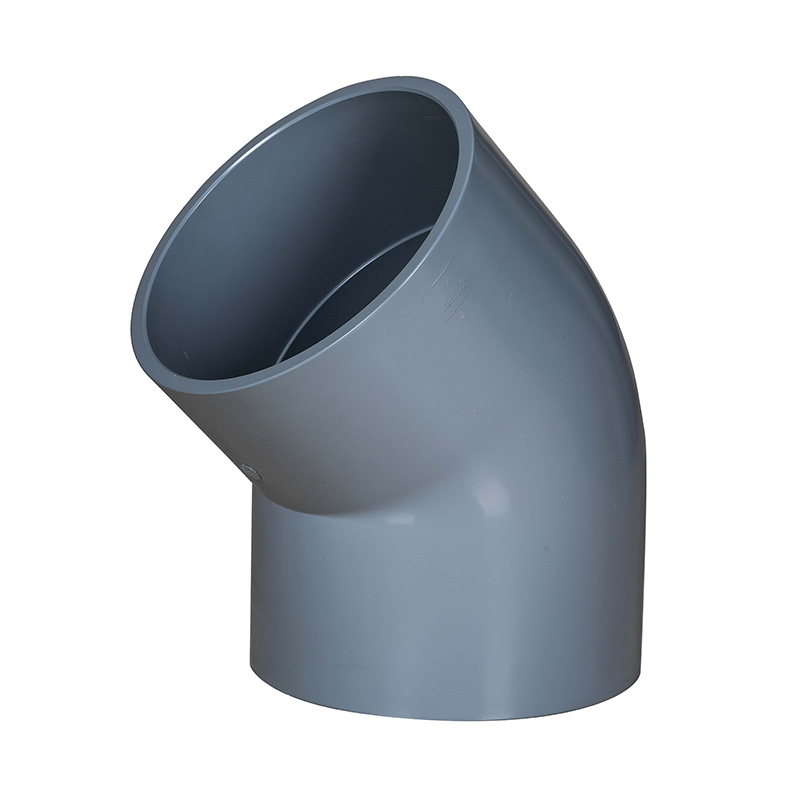

Flow efficiency is a key consideration in CPVC valve design. Kaixin Pipeline Technologies Co., Ltd. applies advanced computational fluid dynamics (CFD) modeling to refine valve disc, seat, and internal channel geometries. Optimized flow paths reduce turbulence, minimize pressure drop, and maintain laminar flow in critical sections of piping systems. Large-diameter valves benefit from uniform fluid distribution, preventing localized turbulence that can cause uneven chemical reactions or erosion. Flow-optimized CPVC valves decrease energy requirements for pumping, reduce wear on connected piping, and maintain precise flow regulation in automated systems. Flow characteristics are tailored for each application, whether chemical transport, water distribution, or high-purity fluid handling. Smooth internal surfaces reduce the accumulation of solids or scaling, extending maintenance intervals. By focusing on hydraulic efficiency, Kaixin’s valves enhance operational performance, improve system reliability, and support process consistency across diverse industrial environments.

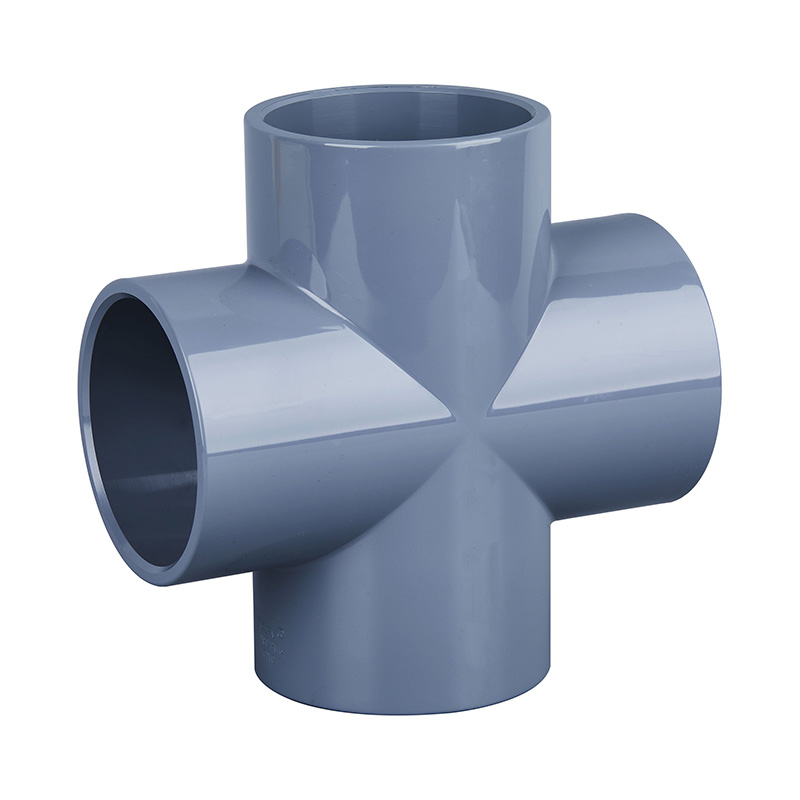

Modular design innovations in CPVC valves allow flexible integration into industrial piping systems. Kaixin Pipeline Technologies Co., Ltd. produces valves with interchangeable actuator mounts, configurable flange designs, and modular seat assemblies. Modular construction allows rapid replacement of worn components, system expansion, or reconfiguration without disrupting entire networks. This flexibility is particularly valuable in industrial plants where layout modifications, maintenance access, or process upgrades are frequent. Modular valves also enable scalable solutions for both small-scale operations and large chemical or water treatment systems. By reducing installation complexity and downtime, Kaixin’s modular designs improve operational efficiency. Modular components simplify spare parts management, providing cost-effective solutions for maintaining fluid control systems. Flexibility in valve design ensures compatibility with existing infrastructure and reduces the need for custom-engineered replacements, making Kaixin CPVC valves highly adaptable to evolving industrial requirements.

CPVC Plastic Valves are increasingly integrated into automated systems, requiring precise compatibility with electric, pneumatic, or hydraulic actuators. Kaixin Pipeline Technologies Co., Ltd. designs valves with standardized actuator mounting interfaces, ensuring secure connection and reliable torque transfer during operation. Compatibility with multiple actuator types allows industrial operators to integrate us valves into automated flow control, remote monitoring, and emergency shutoff systems without modifying piping infrastructure. Standardized mounting reduces installation time, simplifies commissioning, and ensures consistent performance across actuator types. Kaixin also optimizes valve disc geometry and torque specifications to match actuator output, preventing over-torque or leakage issues. Actuator-compatible valves support digital process control, enabling real-time monitoring, automated regulation, and data-driven operational efficiency. Integration with actuators improves responsiveness in chemical dosing, thermal management, or water distribution systems, allowing industrial operators to adjust flow rates, pressure, or temperature remotely. By combining mechanical design and automation readiness, Kaixin ensures our CPVC valves operate efficiently, reliably, and safely in modern industrial environments. This compatibility extends valve life, reduces operational downtime, and supports advanced industrial automation requirements.

CPVC Plastic Valves must endure aggressive chemicals and temperature fluctuations. Kaixin Pipeline Technologies Co., Ltd. enhances chemical and thermal resistance through high-quality CPVC resins with stabilizers and polymer additives that resist acids, alkalis, and oxidizing agents. Critical areas, including valve seats, gaskets, and body walls, are engineered to withstand thermal cycling and chemical attack without dimensional distortion or loss of sealing integrity. This ensures long-term reliability in high-temperature and chemically aggressive processes, including chemical manufacturing, water treatment, and pharmaceutical operations. Enhanced resistance minimizes maintenance requirements, reduces replacement frequency, and improves system uptime. Kaixin also applies design adjustments such as thickened sealing zones and reinforced discs to enhance thermal and chemical durability. These innovations provide industrial operators with valves capable of reliable performance in challenging environments, supporting process efficiency and minimizing operational risks.

Design innovations in CPVC valves also improve lifecycle management and simplify maintenance. Kaixin Pipeline Technologies Co., Ltd. implements modular seat assemblies, quick-release mechanisms, and standardized components to allow inspection, cleaning, or part replacement with minimal disruption. Maintenance activities are streamlined, reducing system downtime and labor requirements. Long-term durability is enhanced through reinforced structures, optimized sealing, and chemical-resistant materials, allowing extended service life with minimal degradation. Lifecycle-focused design reduces operational costs by decreasing component replacement and maintenance frequency. Kaixin’s valves maintain consistent performance throughout their lifespan, providing reliable operation across demanding industrial systems. Maintenance optimization complements structural, sealing, and chemical resistance innovations, delivering a comprehensive, cost-effective, and efficient solution for fluid control applications.

EN

EN English

English

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

+86-18067123177

+86-18067123177