Applications of Plastic Pipe/Pipe Fittings in Industry

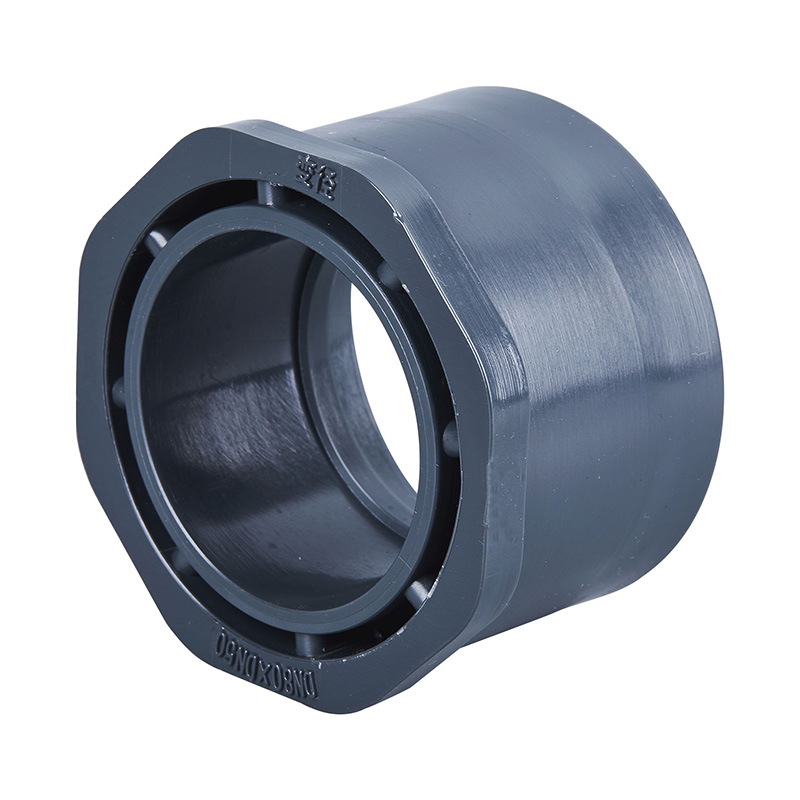

Plastic Pipe/Pipe Fittings have transformed the chemical processing industry by offering superior chemical resistance, durability, and operational flexibility compared with traditional metallic piping systems. Chemical plants often handle aggressive acids, alkalis, solvents, and other reactive substances that can corrode metal pipes, leading to contamination, equipment failure, and production downtime. Plastic Pipe/Pipe Fittings, particularly those constructed from PVC-C, PVDF, PPH, and FRPP, provide a solution that maintains structural integrity and chemical compatibility across a wide range of industrial applications. Kaixin Pipeline Technologies Co., Ltd. has developed a comprehensive line of corrosion-resistant piping systems tailored to meet the stringent demands of chemical plants. Our PVC-C fittings are specifically engineered to resist strong oxidizing and reducing agents, ensuring safe transport of chemical fluids. PVDF fittings offer high-temperature resistance while maintaining exceptional dimensional stability, making our systems suitable for continuous operation in demanding environments. FRPP and PPH fittings provide mechanical robustness for large-diameter pipelines, facilitating efficient transport of fluids in high-volume processing operations.

Key considerations for the use of Plastic Pipe/Pipe Fittings in chemical processing include chemical compatibility, pressure and temperature tolerance, mechanical strength, and long-term reliability. Kaixin Pipeline Technologies Co., Ltd. addresses these considerations by conducting rigorous material testing and selecting polymers that exhibit minimal degradation over time, even under prolonged exposure to aggressive chemicals. Our fittings are designed to connect seamlessly with pipes, valves, and other equipment, ensuring leak-free performance and minimal maintenance requirements. In addition to standard sizes, Kaixin offers customized solutions for specialty applications, allowing chemical engineers to design complex piping networks that meet unique process requirements. The high corrosion resistance of our products reduces the need for frequent inspections, replacements, and chemical-resistant coatings, resulting in significant operational cost savings. Kaixin’s automated production lines and strict quality control further guarantee consistent product performance across all batches, reinforcing reliability in chemical processing systems.

In chemical storage and transport operations, controlling contamination and ensuring material purity are essential. Plastic Pipe/Pipe Fittings produced by Kaixin Pipeline Technologies Co., Ltd. prevent metal ion leaching, scaling, and internal corrosion, protecting product integrity and safety. Our fittings are compatible with both batch and continuous process systems, supporting automated chemical handling, pumping, and dosing operations. Large-diameter fittings and high-pressure pipe assemblies are available to accommodate modern industrial plant requirements, providing flexible and scalable solutions. By integrating Kaixin’s plastic Pipe/Pipe Fittings into chemical processing plants, industrial operators can optimize production efficiency, reduce maintenance interventions, and enhance operational safety, making our systems a preferred choice in competitive global markets.

Plastic Pipe/Pipe Fittings are widely applied in water supply, wastewater management, and industrial effluent systems due to their chemical resistance, long-term durability, and operational efficiency. Conventional metal piping in these applications often suffers from corrosion, scaling, biofilm formation, and leaching of metal ions, which can compromise water quality and increase maintenance requirements. Plastic Pipe/Pipe Fittings, such as those made from PVC-U, PVC-C, FRPP, and PVDF, provide a robust alternative capable of handling clean water, reclaimed water, and chemically treated wastewater without degradation or contamination. Kaixin Pipeline Technologies Co., Ltd. designs and manufactures an extensive range of corrosion-resistant fittings and pipes suitable for municipal water distribution networks, industrial treatment plants, and complex multi-branch piping systems. Our PVC-U and FRPP systems offer excellent resistance to chlorinated water and industrial cleaning agents, ensuring long-term operational stability while preventing internal corrosion and scaling that can restrict flow capacity.

Key considerations for water and wastewater applications include chemical compatibility, pressure and flow stability, thermal performance, and hygiene standards. Kaixin Pipeline Technologies Co., Ltd. addresses these considerations by producing fittings and pipes with precise dimensional tolerances, smooth interior surfaces, and standardized connections that minimize the risk of leaks, clogging, or microbial growth. Our fittings can accommodate high-pressure pumping systems and variable flow rates, supporting both gravity-fed and pressurized networks. Large-diameter PVC-C and PVDF fittings are available for industrial-scale water treatment facilities, enabling efficient transport of treated water and effluent streams across complex plant layouts. Kaixin’s products also maintain structural integrity when exposed to fluctuating temperatures, acidic or alkaline conditions, and mechanical stress from pumping or chemical dosing systems, ensuring reliability in demanding operational environments.

Plastic Pipe/Pipe Fittings are extensively used in the pharmaceutical and food & beverage industries because of their chemical inertness, hygienic properties, and compatibility with sterile and high-purity fluids. These sectors demand piping systems that maintain product integrity, prevent contamination, and withstand aggressive cleaning and sterilization processes, including hot water, steam, and chemical sanitizers. Traditional metal piping can leach ions, corrode, or react with chemical ingredients, which can compromise both safety and quality. Plastic Pipe/Pipe Fittings, particularly those made from PVDF, PPH, PVC-C, and FRPP, address these challenges by providing durable, corrosion-resistant, and non-reactive pathways for fluid transport. Kaixin Pipeline Technologies Co., Ltd. develops specialized piping solutions that meet industry standards for hygiene, purity, and process reliability, offering our clients robust and compliant systems for both production and utility lines.

In the food and beverage sector, Kaixin’s Plastic Pipe/Pipe Fittings support hygienic processing of liquids such as water, dairy, juices, syrups, and chemical additives. The smooth internal surfaces of our fittings prevent microbial growth and scaling, while the chemical inertness ensures that flavor, color, and nutritional quality remain unaffected. Kaixin Pipeline Technologies Co., Ltd. provides fittings compatible with cleaning-in-place (CIP) and sterilization-in-place (SIP) systems, supporting routine sanitation and reducing downtime between production cycles. Our fittings facilitate rapid installation, system expansion, and modular process design, allowing operators to adapt production lines to changing market demands.

EN

EN English

English 中文简体

中文简体

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

+86-18067123177

+86-18067123177