PPH (Polypropylene Homopolymer) plastic pipe valves have become an essential component in modern industrial piping systems. As industries such as chemical processing, environmental protection, water treatment, and high-purity manufacturing continue to raise their requirements for material performance, the limitations of traditional metal valves—particularly in corrosion resistance, maintenance cost, and service life—have become increasingly evident. In contrast, PPH plastic pipe valves stand out due to their superior material properties, system compatibility, and long-term operational reliability.

As a professional manufacturer and system solution provider specializing in industrial plastic piping systems, Kaixin Pipeline Technologies Co., Ltd. has long been committed to the research, development, and production of PPH pipes, fittings, and valves. With stable product quality, a comprehensive specification range, and extensive project experience, the company provides safe, reliable, and corrosion-resistant piping control solutions for customers worldwide.

What Is a PPH Plastic Pipe Valve and Why Is It Different from Other Valves?

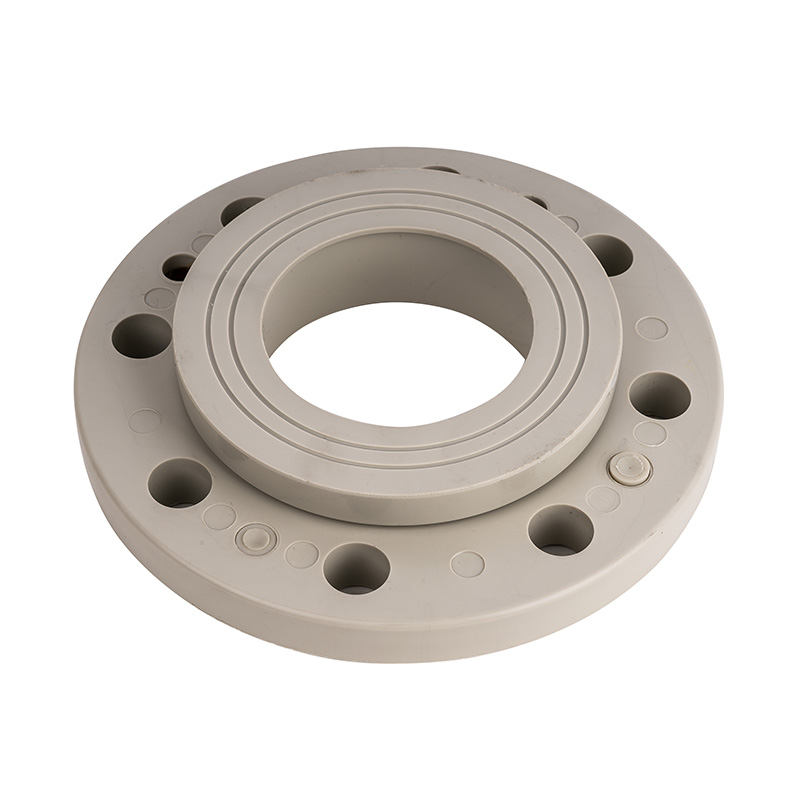

A PPH Plastic Pipe Valve is a flow control device manufactured from polypropylene homopolymer (PPH) material, designed to regulate, isolate, or control the flow of fluids in a piping system. Common types include PPH ball valves, butterfly valves, diaphragm valves, check valves, and gate valves, all of which are widely used in integrated PPH piping systems.

Compared with standard PP (PP-R) or PVC valves, PPH material features a higher crystallinity and more stable molecular structure, enabling PPH valves to perform more reliably under high-temperature and highly corrosive conditions. Especially in chemical fluid transportation systems, PPH plastic pipe valves demonstrate excellent resistance to acids, alkalis, salt solutions, and many organic solvents. This effectively eliminates common issues found in metal valves, such as rusting, pitting, and electrochemical corrosion.

During the design and manufacturing of PPH valves, Kaixin Pipeline Technologies Co., Ltd. strictly follows industrial piping standards. From raw material selection and mold structure design to sealing systems and final inspection, every production step is carefully controlled to ensure long-term sealing performance and smooth operation.

From a structural perspective, PPH Plastic Pipe Valves typically offer the following features:

- Smooth internal flow paths that reduce pressure loss

- Lightweight construction that lowers installation and transportation costs

- Compatibility with fusion welding or flange connections for leak-free systems

The table below highlights the key differences between PPH plastic pipe valves and other common valve materials:

| Comparison Item |

PPH Plastic Pipe Valve |

PVC Valve |

Metal Valve |

| Corrosion Resistance |

Excellent, suitable for aggressive media |

Moderate |

Material-dependent |

| Temperature Resistance |

Up to 90–95°C |

Usually ≤60°C |

High |

| Weight |

Lightweight |

Lightweight |

Heavy |

| Maintenance Cost |

Low |

Low |

High |

| Service Life |

Long |

Medium |

Affected by corrosion |

For these reasons, PPH Plastic Pipe Valves are not merely individual components but a critical part of modern industrial piping systems transitioning toward lightweight, corrosion-resistant, and low-maintenance solutions.

What Are the Key Advantages of Using PPH Plastic Pipe Valves in Industrial Applications?

In industrial fluid control systems, valve performance directly affects system safety, stability, and operating costs. The widespread adoption of PPH Plastic Pipe Valves across multiple industries is primarily driven by their advantages in material performance, structural design, and system compatibility.

First and foremost, exceptional chemical corrosion resistance is the most significant advantage of PPH plastic pipe valves. PPH material exhibits outstanding resistance to most inorganic acids, alkalis, and salts, making it ideal for applications in chemical processing, electroplating, pharmaceutical manufacturing, and wastewater treatment. Compared with metal valves that require frequent replacement or maintenance, PPH valves significantly reduce downtime risks and long-term maintenance expenses.

Secondly, excellent thermal resistance and dimensional stability allow PPH Plastic Pipe Valves to operate reliably at elevated temperatures without deformation or performance degradation. During product development, Kaixin Pipeline Technologies Co., Ltd. carefully considers demanding industrial operating conditions, optimizing valve body structures and sealing systems to ensure dependable performance even under fluctuating temperature and pressure environments.

Another critical advantage is system compatibility. PPH valves integrate seamlessly with PPH pipes and fittings, forming a unified material system. This avoids leakage risks caused by differences in thermal expansion coefficients between dissimilar materials. Providing such complete same-material system solutions is a core value emphasized by Kaixin Pipeline Technologies Co., Ltd. when supporting engineering projects.

Additional practical advantages of PPH Plastic Pipe Valves include:

| Advantage Category |

Key Benefits |

| Easy Installation |

Lightweight design improves installation efficiency |

| Fluid Performance |

Smooth inner surfaces resist scaling |

| Operational Safety |

No rust, no contamination |

| Life-Cycle Cost |

Low initial and maintenance costs |

| Environmental Performance |

Recyclable material |

Through years of service across diverse industries, Kaixin Pipeline Technologies Co., Ltd. not only supplies standardized PPH valve products but also offers customized specifications and professional application guidance. This helps clients achieve an optimal balance between system performance and overall cost while maintaining high safety standards.

Where Are PPH Plastic Pipe Valves Most Commonly Used and Why Are They Trusted?

As industrial systems place increasing emphasis on safety and reliability, the application scope of PPH Plastic Pipe Valves continues to expand. From traditional chemical plants to advanced electronics manufacturing, these valves have become a standard choice in many engineering projects.

In the chemical and chemical processing industries, PPH plastic pipe valves are widely used in acid and alkali pipelines, reactor support systems, and tank inlet and outlet lines. Their excellent corrosion resistance effectively prevents leakage and enhances operational safety. PPH valve solutions from Kaixin Pipeline Technologies Co., Ltd. have been successfully implemented in numerous chemical projects, delivering long-term stable performance.

In water treatment and environmental engineering, PPH Plastic Pipe Valves are commonly applied in wastewater treatment systems, exhaust gas scrubbing units, chemical dosing lines, and circulating water pipelines. Compared with metal valves, PPH valves are less prone to scaling and are unaffected by humid environments, making them ideal for continuous, long-term operation.

Furthermore, in electronics, semiconductor, and pharmaceutical industries, fluid purity is critical, and even trace metal ion contamination can compromise product quality. Thanks to the high-purity characteristics of PPH material, PPH valves are an ideal solution for high-purity water and chemical distribution systems.

Typical application areas for PPH Plastic Pipe Valves include:

| Industry Sector |

Typical Applications |

| Chemical Industry |

Acid/alkali pipelines, reaction systems |

| Environmental Engineering |

Wastewater treatment, gas scrubbing |

| Water Treatment |

Chemical dosing, circulation systems |

| Electronics & Semiconductors |

High-purity water, chemical transport |

| Pharmaceutical Industry |

Process piping systems |

As a professional piping system manufacturer, Kaixin Pipeline Technologies Co., Ltd. goes beyond supplying high-quality PPH Plastic Pipe Valves by offering complete system-level support, including product selection guidance, technical parameter matching, and long-term supply stability. This transition from single-product supply to integrated system solutions is a key reason why an increasing number of customers choose Kaixin as their trusted partner.

EN

EN English

English

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

+86-18067123177

+86-18067123177