Kaixin, a high-tech enterprise specialized in the R&D, production and sales of polymer pipeline valves.

|

Serial number |

Abnormal phenomenon |

the reason |

Solution |

Remarks |

|

1 |

Surface discoloration |

The temperature of the barrel or head is too high, causing the material to decompose |

Cool down |

|

|

The material is not stable enough and decomposes |

Check whether the PVC resin or stabilizer causes insufficient stability, replace the resin or stabilizer, or increase the number of stabilizers. |

|

||

|

Temperature instrument control failure, decomposition caused by over-temperature |

Adjust and repair the instrument |

|

||

|

2 |

There are yellow-brown stripes or colored spots on the surface of the pipe |

There are dead corners in the mold or the shunt shuttle or cause stagnation and paste, resulting in local decomposition streaks |

Clean up |

Local paste, dead corners and increased friction on the surface of the pipe will decompose and form streaks |

|

Uneven mixing or impurities in the material can cause partial decomposition and form surface color spots |

Determine the specific reasons, improve the mixing process or replace the problematic raw materials |

|

||

|

3 |

Matte appearance |

Low die temperature |

Increase the die temperature and increase the amount of ACR to increase the shear |

Bright ACR processing aid can significantly improve surface finish even at lower temperatures |

|

Shear rate is too high, melt fracture |

Properly increase the material temperature, increase the amount of ACR or reduce the traction speed |

|

||

|

The temperature of the die is too high or the inner surface finish is poor |

Cool down, reduce roughness |

|

||

|

Poor plasticization |

Increase temperature, increase processing aids |

|

||

|

The external lubricant content is too low |

Under the premise of ensuring the plasticization of materials, add external lubricants appropriately |

There are too few external cuts, which makes the material easy to bond to the metal surface and affects the surface smoothness. |

||

|

The particle size of CaC03 is too large or the particle size distribution is too wide |

Replace the applicable calcium carbonate |

|

||

|

4 |

Wrinkles on the pipe surface |

Uneven temperature around the die |

Check the heating ring |

|

|

Poor cooling |

And increase the cooling water or reduce the cooling water decline |

|

||

|

Towing is too slow |

Speed up traction |

|

||

|

Impurities in the material |

Exchange of raw materials |

|

||

|

Core touch temperature is too low |

Increase core mold temperature |

|

||

|

Body temperature is too low |

Increase the body temperature |

|

||

|

Towing speed is too fast |

slow down |

|

||

|

5 |

Rough inner wall |

Core touch temperature is too low |

Increase the core temperature or add work aids |

Low temperature causes poor plasticization, and the inner wall is difficult to heat up at the die, so roughness occurs |

|

The barrel temperature is too low, and the plasticization is not good |

increase temperature |

When raising the temperature makes it difficult to control the temperature in the subsequent stage, you can increase the ACR processing aid without raising the temperature, and the same effect can be obtained |

||

|

The temperature of the money rod is too high |

Enhanced screw cooling |

|

||

|

6 |

Bubbles on the tube wall |

Overwhelming |

dry |

|

|

The vacuum at the vacuum exhaust hole after the second section of the barrel is too low or blocked |

Check the working condition of the pump, whether the pipeline is blocked (caused by pumping powder)) |

|

||

|

Decomposition (head temperature is too high) |

Reduce the temperature |

|

||

|

7 |

Sentences with uneven wall thickness |

Mouth touch, core selection, different hearts |

Modulation |

|

|

The temperature of the machine head is uneven, and the output is fast or slow |

Check the heating ring, check the screw for pulsation |

|

||

|

Unsteady traction speed |

Check and repair tractor |

|

||

|

The vacuum of the vacuum tank fluctuates |

Check the vacuum pump and its pipeline |

|

||

|

8 |

Uneven inner wall |

Screw temperature is too high |

Decrease screw temperature |

|

|

The screw speed is too fast, causing melt rupture |

Sim Speed |

|

||

|

9 |

Pipe droop |

Uneven wall thickness |

Same as 7 |

|

|

Uneven temperature around the nose |

Check the heating coil |

|

||

|

The fuselage, sizing groove, and traction are not on the same axis |

Adjust to an axis |

|

||

|

The cooling holes at both ends are not in a straight line |

Adjust to an axis |

|

||

|

Uneven water output from cooling tank nozzle |

Adjust and replace the nozzle |

|

||

|

10 |

Bubbles in section |

Material high moisture |

Dry or change nozzle |

|

|

The mixing temperature is low, and the water is not discharged |

Increase mixing temperature |

|

||

|

Exhaust hole vacuum is low or pipeline is blocked |

Check the vacuum pump and its pipeline |

|

||

|

The temperature of the fuselage or horizontal head is too high |

Reduce the temperature |

|

||

|

Poor thermal stability of mixed ingredients |

Check and modify the formula |

|

||

|

11 |

The impact strength of the pipe is not fully qualified |

Low processing temperature |

Increase the processing temperature or increase the ACR processing aid |

|

|

Poor quality of the original paving |

Replace raw materials |

|

||

|

Low back pressure |

Change process conditions |

If the back pressure is low due to the mold, and the process cannot be adjusted, the mold can only be repaired |

||

|

Poor formula |

Improve formula |

|

||

|

High processing temperature (plasticization, excessive or decomposition) |

Lower Wenqian |

|

||

|

When using CPE impact modification, the screw speed is too fast and the shear rate is too high, so that the CPE is unevenly dispersed and is in a piled state, which reduces the impact resistance. |

Reduce screw cuff speed |

Reducing the screw speed will reduce the production capacity. Switch to ACR as the best solution for the impact modifier. The ACR temperature and shear rate have good adaptability. |

||

|

11 |

The impact strength of the pipe is not fully qualified |

Low processing temperature |

Increase the processing temperature or increase the ACR processing aid |

|

|

Poor quality of the original paving |

Replace raw materials |

|

||

|

Low back pressure |

Change process conditions |

If the back pressure is low due to the mold, and the process cannot be adjusted, the mold can only be repaired |

||

|

Poor formula |

Improve formula |

|

||

|

High processing temperature (plasticization, excessive or decomposition) |

Reduce the temperature |

|

||

|

When using CPE impact modification, the speed of the rod is too fast, and the shear rate is too high, so that the CPE is unevenly dispersed, and it is in a piled state, and the impact resistance is reduced. |

Reduce screw speed |

Reducing the screw speed will reduce the production capacity. Switch to ACR as the best solution for the impact modifier. ACR has good adaptability to temperature and shear rate. |

||

|

Cooling water temperature is too low (mostly in winter), excessive internal stress due to sudden cooling |

Adjust the cooling water temperature |

|

||

|

Poor exhaust, causing pores in the pipe |

Adjust the vacuum degree of the exhaust hole, and eliminate it when there is blockage |

|

||

|

Defective particles, forming micro-cracks in the pipe wall, reducing the impact strength of the pipe |

The sluggish particles may come from impurities, agglomerated CaCO3, slip agent, unplasticized PVC particles, etc., according to specific reasons, take measures, such as sieving the dry mixture |

Defective particles refer to the particles that are larger and affect the material. Defective particles will also make the pipe hydraulic test unqualified. |

||

|

12 |

The pipe pressure test is not suitable |

Poor plasticization and reduced tensile strength |

Increase or increase the number of processing aids |

|

|

The quality of PVC resin is not good, the poly content is low, or the molecular weight distribution is too wide, or the molecular structure is trapped |

Replace PVC |

|

||

|

The modifier has low tensile strength, which reduces the tensile strength of the pipe. |

Replace the impact modifier with higher tensile strength. For ACR and CPE, the impact on the tensile strength of the pipe is much smaller. |

|

||

|

The factors in Article 11 will also cause low tensile strength of the pipe, which will make the hydraulic test unqualified. |

|

|

||

|

13 |

Dichloromethane immersion test is not qualified |

Poor plasticization |

Increase processing temperature or increase ACR processing aid |

For formulas with high filling components such as calcium carbonate and carbon black, it is often difficult to increase the degree of plasticization by increasing the processing temperature. At this time, it is necessary to add ACR processing aids. |

|

14 |

Unqualified longitudinal retraction rate |

The composition of high-resistance substances such as elastic rubber body is too high, such as CPE |

Replace the components in the formula that have too high a recovery rate |

|

|

The extrusion speed does not match the index speed, and the traction speed is too fast |

Reduce traction speed |

|

||

|

Poor cooling |

Decrease the temperature of the cooling water or increase the amount of cooling water |

|

||

|

The head temperature is too high |

Reduce the temperature |

|

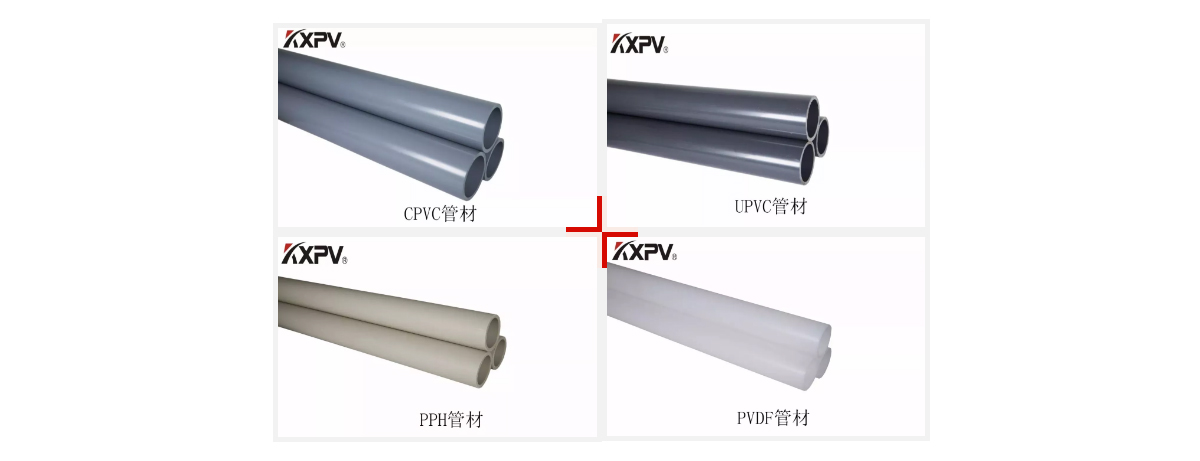

Products Show

EN

EN English

English

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

+86-18067123177

+86-18067123177