Understanding the Role of Pipe Accessories in Modern Piping Systems

Pipe accessories are essential components in modern piping systems, providing functionality, safety, and flexibility beyond what the pipes themselves can achieve. While pipes serve as the main channels for fluid or gas transport, accessories enable connection, control, direction change, pressure regulation, and system protection. Without high-quality accessories, even the most robust piping system may fail to operate efficiently or safely. This makes the expertise of a professional Pipes Accessories Factory crucial in ensuring system reliability.

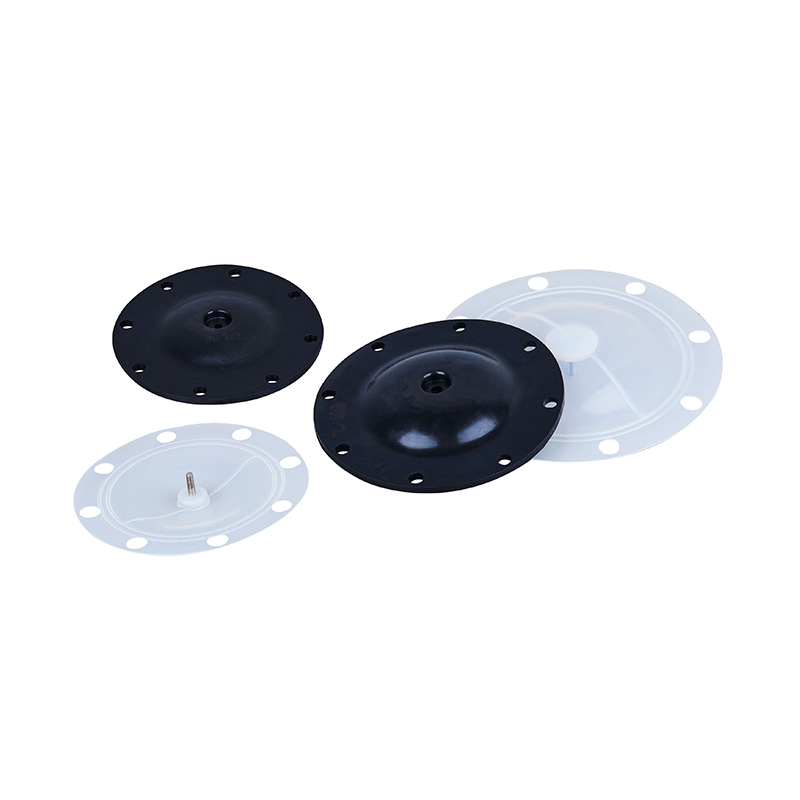

Common types of pipe accessories include fittings, elbows, tees, reducers, flanges, valves, clamps, adapters, and expansion joints. Each accessory is designed for a specific purpose. Fittings allow the connection of pipes of different diameters or materials, while valves regulate flow and prevent backflow. Flanges create detachable joints for maintenance, and expansion joints absorb thermal expansion and vibration. In industrial applications such as oil and gas, chemical plants, water treatment, and HVAC systems, the choice of accessory directly affects system performance, energy efficiency, and safety standards.

Kaixin Pipeline Technologies Co., Ltd. has decades of experience producing a wide range of pipe accessories tailored to international standards. By combining precision manufacturing, high-quality materials, and advanced engineering designs, the company ensures that every fitting, flange, or valve delivers reliable performance in complex industrial environments. Kaixin Pipeline Technologies Co., Ltd. also emphasizes modularity in its designs, allowing engineers to construct flexible piping networks that can adapt to future system expansions or modifications.

Additionally, pipe accessories contribute to installation efficiency and operational scalability. High-quality accessories reduce installation time, lower maintenance costs, and minimize the risk of leakage or system failures. By ensuring proper alignment, sealing, and connection strength, Kaixin Pipeline Technologies Co., Ltd. helps its clients achieve piping systems that are safe, durable, and fully compliant with both local and international codes.

Common Pipe Accessories Overview:

| Accessory Type |

Function |

Typical Material |

Applications |

| Fittings (Elbows, Tees, Reducers) |

Connect pipes & change direction |

Stainless steel, PVC, PP, Carbon steel |

Industrial, chemical, water supply |

| Valves |

Control and regulate flow |

Brass, Stainless steel, PVC |

Oil & gas, HVAC, chemical |

| Flanges |

Detachable joints for maintenance |

Carbon steel, Alloy steel |

High-pressure pipelines, industrial systems |

| Clamps & Supports |

Fixation and alignment |

Galvanized steel, Stainless steel |

Construction, mechanical support |

| Expansion Joints |

Absorb thermal expansion & vibration |

Rubber, PTFE, Stainless steel |

HVAC, chemical transport, high-temperature systems |

Materials and Manufacturing Processes Used in Pipe Accessories Production

Material selection and manufacturing processes are critical factors in the performance, durability, and safety of pipe accessories. A professional Pipes Accessories Factory must carefully consider environmental conditions, pressure ratings, temperature ranges, and the type of medium being transported. Each variable influences the choice of materials and the appropriate manufacturing method.

Metal accessories, widely used in industrial and high-pressure systems, typically include carbon steel, stainless steel, brass, ductile iron, and aluminum alloys. Each metal offers different advantages: carbon steel is cost-effective for general applications; stainless steel provides superior corrosion resistance; brass is ideal for water supply and low-pressure applications; and aluminum alloys reduce weight while maintaining structural integrity. Kaixin Pipeline Technologies Co., Ltd. specializes in producing accessories from these metals with advanced forging, casting, and CNC machining processes. Forged accessories offer high strength and reliability for critical industrial applications, while castings allow for complex geometries and lower production costs.

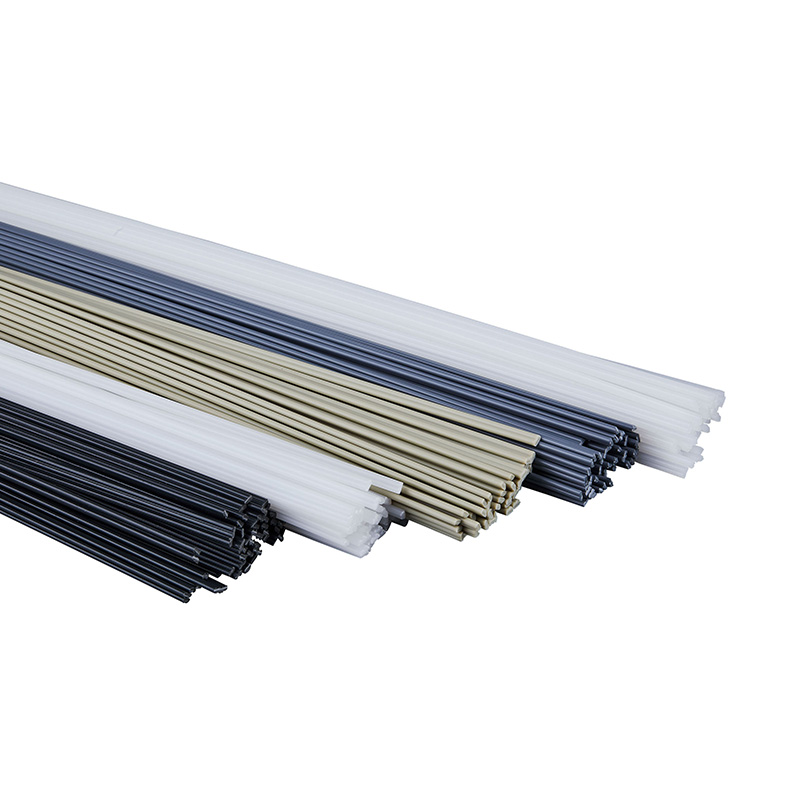

Plastic pipe accessories, including PVC, CPVC, PP, PE, and nylon, are used in applications requiring chemical resistance, lightweight solutions, and low-pressure systems. Injection molding and extrusion are the primary manufacturing processes for plastic accessories. These methods allow mass production with tight tolerances, smooth surfaces, and consistent quality, which is essential for ensuring leak-free connections in piping networks.

Surface finishing is also crucial. Metal fittings often undergo galvanizing, powder coating, or polishing to improve corrosion resistance, while plastic components may receive UV stabilization or flame retardant treatment. Kaixin Pipeline Technologies Co., Ltd. implements rigorous quality assurance at every stage, including raw material inspection, in-process checks, and final product testing, ensuring that each accessory meets international standards such as ISO, ANSI, ASME, and DIN.

Comparison of Common Materials and Manufacturing Processes:

| Material |

Manufacturing Process |

Key Advantages |

Typical Applications |

| Stainless Steel |

Forging, CNC machining |

High corrosion resistance, high strength |

Oil & gas, chemical, water pipelines |

| Carbon Steel |

Casting, CNC machining |

High pressure capacity, cost-effective |

Industrial pipelines, construction |

| Brass |

Casting, CNC machining |

Corrosion resistance, lightweight |

Water supply, plumbing systems |

| PVC / CPVC |

Injection molding |

Chemical resistance, lightweight |

Water treatment, low-pressure chemical transport |

| PP / PE |

Extrusion, Injection molding |

Flexibility, low friction |

HVAC, drainage, chemical transport |

By integrating material expertise, precise manufacturing processes, and advanced quality control, Kaixin Pipeline Technologies Co., Ltd. delivers pipe accessories that balance strength, durability, and efficiency for demanding applications.

Industry Standards, Quality Control, and Future Trends in Pipe Accessories

Strict adherence to industry standards and rigorous quality control is vital for any Pipes Accessories Factory serving global markets. International standards such as ISO, ANSI, ASME, ASTM, DIN, BS, and JIS define specifications for dimensions, materials, pressure ratings, and testing methods. Compliance ensures that products from Kaixin Pipeline Technologies Co., Ltd. are compatible with international piping systems and meet safety requirements.

Quality control covers the entire manufacturing lifecycle. Kaixin Pipeline Technologies Co., Ltd. inspects raw materials, monitors production processes, and performs final product testing, which includes dimensional verification, pressure testing, leakage assessment, tensile strength evaluation, and corrosion resistance checks. Additionally, traceability systems are implemented so that each batch can be tracked from raw material to finished product.

Looking forward, the pipe accessories industry is evolving rapidly. Lightweight alloys, composite materials, and environmentally friendly plastics are increasingly adopted to meet sustainability and energy-efficiency goals. Rapid customization and responsive manufacturing are becoming essential to meet specific project requirements, especially in the renewable energy, green building, and advanced industrial sectors.

Digitalization and smart manufacturing are also transforming the industry. Automated production lines, data-driven quality management, and predictive maintenance technologies help factories like Kaixin Pipeline Technologies Co., Ltd. improve production efficiency, reduce defects, and maintain consistent global quality standards. These trends ensure that pipe accessories not only meet today’s needs but are prepared for future industry challenges.

Industry Standards and QA Practices Overview:

| Aspect |

Key Practices |

Benefits |

| Standards Compliance |

ISO, ANSI, ASME, DIN, BS, JIS |

Global compatibility, safety |

| Quality Control |

Raw material inspection, in-process checks, final testing |

Reliability, reduced defects |

| Material Innovation |

Lightweight alloys, composite plastics |

Sustainability, efficiency |

| Manufacturing Trends |

Automation, CNC, injection molding, extrusion |

Precision, scalability, cost reduction |

EN

EN English

English 中文简体

中文简体

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

+86-18067123177

+86-18067123177