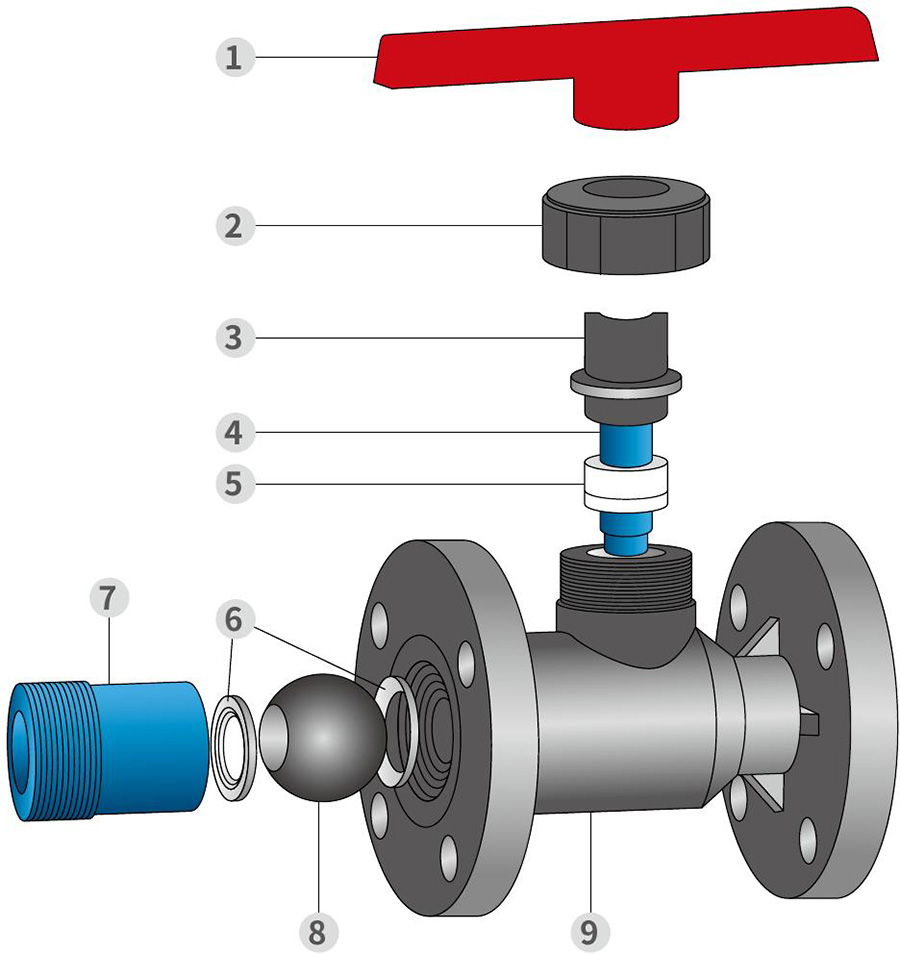

Best Quality heat resistant CPVC Worm-Gear Type Flange Ball Valve DN25-DN1000 ANSI Standard manual Industrial Plastic Valve

Model NO.:D371X-10F

Material:Plastic

Connection Form:Flange

Driving Mode:Manual

Nominal Pressure:10kg

Channel:Straight Through Type

Structure:Fixed Ball Valve

Function:Bypass-Valve

Temperature:High Temperature

Application:Industrial Usage, Water Industrial Usage, Household Usage

Specification:DN25-DN1000

Standard:ANSI

Origin:Beilun Ningbo China

HS Code:8481804090

EN

EN English

English

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

Headquarters: No. 539 Bohai Road, Beilun District, Ningbo City, Zhejiang Province, P.R. China

+86-18067123177

+86-18067123177